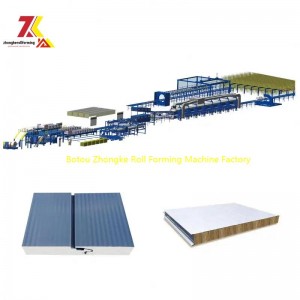

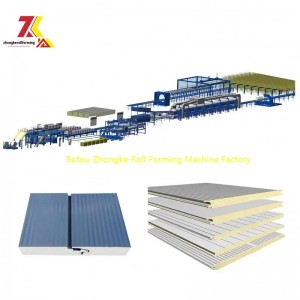

2024 Kev kub ceev Tsis siv neeg polyurethane tshuab Phenolic Insulated Polyurethane Sandwich Ua Npuas Ncauj Tshuab

Dab tsi yuav tsum tau siv nyob rau hauv Phenolic Insulated Vaj Huam Sib Luag Tshuab?

Lub pob zeb wool board ntau lawm kab yog ib tug ua tiav system rau zus tau tej cov pob zeb wool boards. Nws siv lub tshuab hluav taws xob metering tsis siv neeg pub mis ntxiv rau cov ntaub ntawv raw rau lub qhov cub kaw rau melting. Tom qab tsim cov fibers los ntawm plaub-yob centrifuge, ntxiv qhov tsim nyog tus nqi ntawm binder. Cov paj rwb sau tshuab, pendulum daim ntaub paj rwb tshuab, thiab pleating pre-pressing tshuab raug xa mus rau qhov cub ua kom sov ua cov laug cam, thiab tom qab ntawd txias, txiav, pov tseg ntug rov siv dua, tsis siv neeg board stacking tshuab, thiab tsim cov ntim pob zeb wool boards.

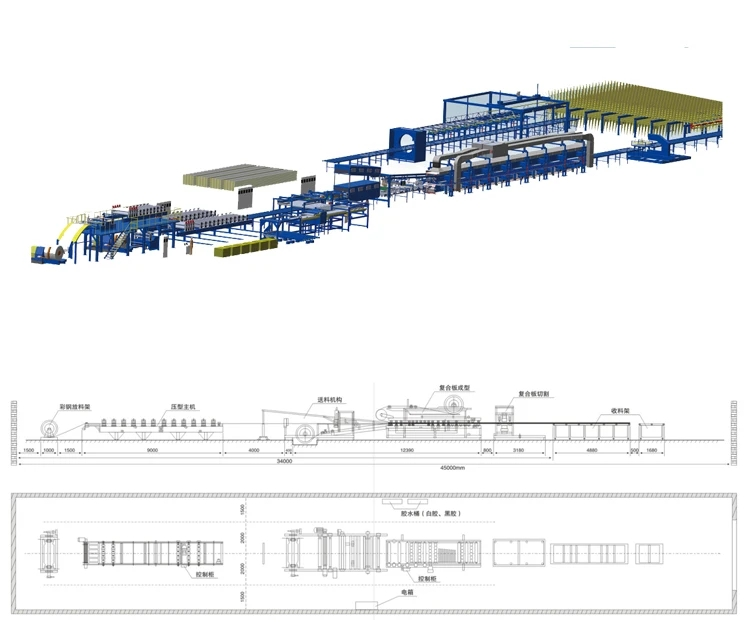

Phenolic Insulated Vaj Huam Sib Luag Tshuab feem ntau suav nrog:

1. Raw khoom noj system: tsis siv neeg batching tshuab, tswj txee, pub tshuab.

2. Melting system: rauv thav duab, cupola, melting furnace khoom theem tswj qhov system, plua plav collector, khib nyiab roj combustion rauv, khib nyiab induced cua pipeline, pa roj induced cua ntsawj ntshab ntxuam, tshav kub exchanger tswj txee, melting rauv cua txias system, melting rauv cua mov kiv cua, melting rauv cua mov pipeline.

3. Paj rwb ua tshuab: high-speed centrifuge, kiv cua, paj rwb tshuab tshuab, centrifuge lubrication system, dej twj tso kua mis thiab cua txias system, hluav taws xob tswj txee, slag tshem tawm.

5. paj rwb sau thiab paj rwb faib tshuab: paj rwb sau tshuab thiab pendulum paj rwb distributing tshuab tswj txee, paj rwb sau induced cua ntxuam, paj rwb sau plua plav collector.

6. Board ua system: ntaub paj rwb conveyor, pressurized folding tshuab, curing furnace, active fais fab sib dhos, tswj txee.

7. Kev tawg-pov thawj ntawm kev kho cua sov: cov khoom siv hluav taws xob tshawb pom, cov kiv cua tawg, tawg-pov thawj kav, tswj txee.

8. Tej tshuab: txias conveyor, cua txias kiv cua, longitudinal txiav tshuab, kab rov tav txiav tshuab txiav thiab ntsuas ntaus ntawv, tswj txee, txiav tshuab fais fab system.

9. Txiav plua plav tshem tawm qhov system: lub hnab lim, plua plav tshem tawm cov kav dej, kiv cua tshem tawm plua plav.

10. Cov cua kub txheej txheem ntawm kev kho cua sov: kiv cua kub-resistant, roj kub cua qhov cub, roj burner, cua kub pipeline.

11. Khib ntug rov qab system: shredder, ntug rov qab ntxuam, ntug rov qab pipeline.

12. Cov cuab yeej pabcuam: cov khoom siv ua kua nplaum, tsis siv neeg palletizing tshuab, ntim tshuab, tshuab slitting.

Ntim & Shipping

Phenolic Insulated Vaj Huam Sib Luag Tshuab

Ntim Cov Lus Qhia: 1 * 40 GP thawv; lub ntsiab tshuab liab qab thiab fastened nrog hlau hlau nyob rau hauv lub thawv.

Kev Qhia Txog Tus Me Nyuam: 30-35 hnub tom qab kev txiav txim ntawm Cov Khoom Siv Tsheb kauj vab log tsheb

Peb Cov Kev Pabcuam

1- Tag nrho cov lus nug tau teb tom qab 12 teev

2- Cov kws tshaj lij yuav xa qee cov ntsiab lus hais txog lub tshuab ua hom lus sib txawv (Suav, Askiv, Fabkis, Mev, Arabic)

3- Tus kws ua haujlwm txawv teb chaws muaj kev pabcuam tomqab muag

4- Qee cov vis dis aus yuav xa tuaj rau koj ntsig txog cov khoom

5- Warranty rau ib xyoos.

6- Cov lus nug, hu rau txhua lub sijhawm.

7- Txhua qhov kev mus ntsib, tuaj yeem muab tsab ntawv caw.

8- Spare- qhov xav tau, tuaj yeem muab tau

9- Muab tus nqi tsim nyog nrog lub tshuab zoo