Tsis siv neeg loj adjustable sawv ntsug seam ru tsev vaj huam sib luag yob txoj kev tshuab

Cov lus piav qhia ntawm cov khoom los ntawm tus neeg muag khoom Txheej txheem cej luam

KHOOM PLIG NTAWM Zhongke sawv seam yob txoj kev tshuab

Zhongke sawv seam yob txoj kev tshuab

Stand Seaming Roll Forming Tshuab yog ib qho tshwj xeeb ntawm cov cuab yeej tsim los rau kev tsim cov khoom siv hlau zoo nrog cov qauv seam meej. Nws siv ib tug series ntawm precision-engineered rollers teem nyob rau hauv ib tug stand-mounted configuration, tso cai rau kev nruam thiab automated shaping ntawm hlau los xij rau hauv cov kev xav tau profiles. Lub tshuab pub cov hlau coils los yog cov ntawv los ntawm nws cov chais, txuas ntxiv khoov thiab folding cov khoom tsim kom muaj zog, seamless pob qij txha los yog intricate seam qauv.Qhov txheej txheem no ua kom zoo ib yam thiab qhov tseeb ntawm qhov tseeb, zoo tagnrho rau tsim cov khoom xws li vov tsev vaj huam sib luag, siding, gutters, thiab lwm yam architectural metalwork. Lub qhov rooj seaming mechanism muab ntxiv zog rau cov khoom tiav los ntawm nruj nreem kaw cov npoo ua ke, txhim kho nws cov kav ntev thiab ua haujlwm rau huab cua.Operators tuaj yeem kho lub tshuab teeb tsa kom haum rau cov khoom sib txawv thicknesses thiab seam specifications, kom paub tseeb versatility nyob rau ntau yam kev xav tau. Tsis tas li ntawd, qhov xwm txheej ntawm cov txheej txheem yob txoj kev ua haujlwm tau txo qis cov nqi zog thiab ua kom cov khoom nrawm, ua rau nws yog ib qho tseem ceeb rau cov khoom siv hlau niaj hnub.

PURLIN SPECIFICATIONS NTAWM Zhongke sawv seam yob txoj kev tshuab

Lub Zhongke ntawm Thawv Vaj Huam Sib Luag Ua Tshuab Txias Roll Forming Tshuab yog lub tshuab ua haujlwm siab, ua haujlwm siab siv tshuaj tsim los tsim cov vuas zoo. Nrog rau kev tsim khoom thiab kev lag luam muaj peev xwm, lub tshuab no muaj cov txheej txheem yob txoj kev, hloov cov cuab yeej sai, thiab cov neeg siv khoom siv tau zoo digital tswj vaj huam sib luag. Tsim los ntawm cov khoom siv ruaj khov thiab muaj cov qauv tsim, nws ua kom ruaj khov thiab ua haujlwm tau zoo. Lub tshuab muaj peev xwm ua tau ntau yam khoom siv, muab cov txiaj ntsig zoo ib yam thiab meej. Zoo tagnrho rau kev tsim kho tej yaam num, nws streamlines cov txheej txheem ntau lawm thiab maximizes productivity.

| Portable tag nrho tsis siv neeg SSR Standing seam hlau ru tsev ntawv yob txoj kev tshuab rau muag nqe | ||

| 1.Formed Material | PIB, GI, AI | Thickness: 0.4-0.8mm Dav: raws li daim duab profile |

| 2.Decoiler | Hydraulic tsis siv neeg decoiler | Kev tuav decoiler (yuav muab rau koj dawb) |

| 3. Lub cev loj

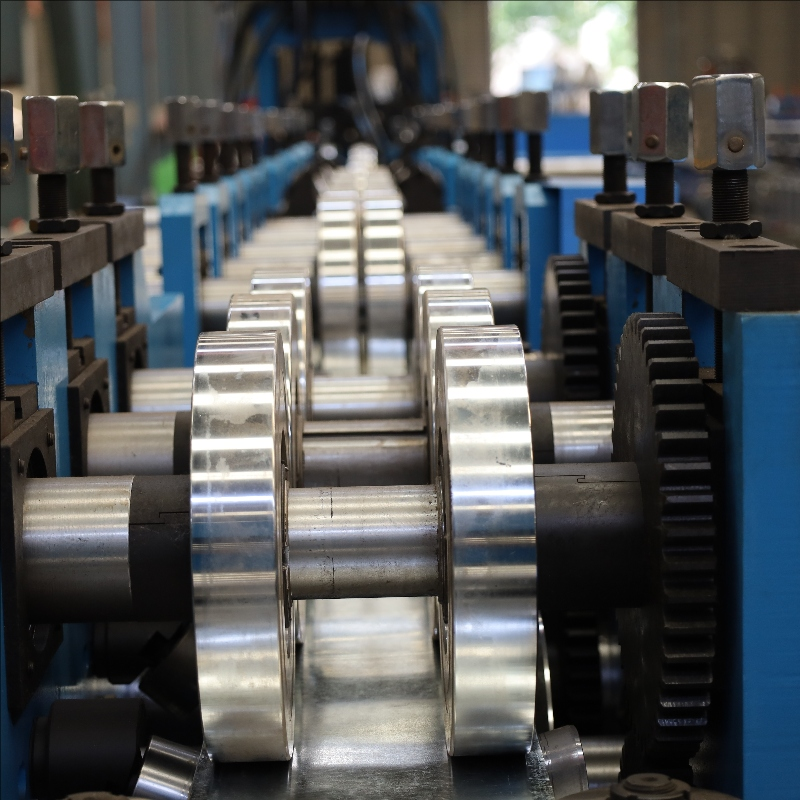

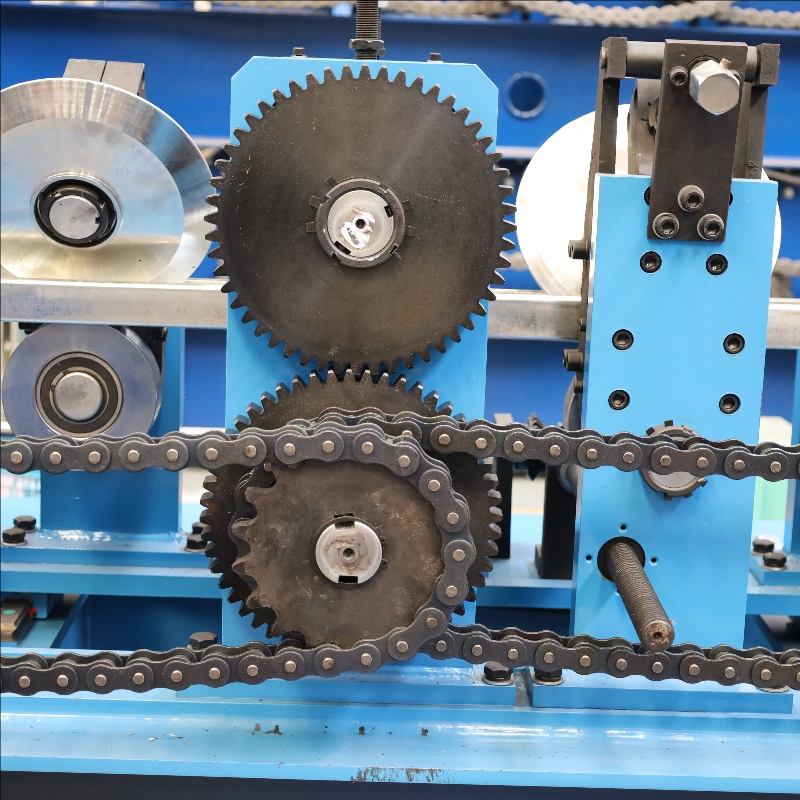

| Roller chaw nres tsheb | 12 kab (Tsim raws li daim duab profile) |

| Txoj kab uas hla ntawm ncej | 70mm khoom ncej | |

| Cov khoom siv ntawm rollers | 45 # steel, nyuaj chrome plated rau saum npoo | |

| Tshuab lub cev ncej | 350H hlau | |

| Tsav | Chain kis tau tus mob | |

| Qhov Loj (L * W * H) | 5500 * 1600 * 1600 (kev cai) | |

| Qhov hnyav | 3.5 t ua | |

| 4. Cutter | Tsis siv neeg | cr12mov khoom, tsis muaj khawb, tsis deformation |

| 5. Lub zog

| Lub cev muaj zog | 5.5 KW TSI |

| Hydraulic system zog | 4 KW | |

| 6. Lub zog | 380V 50Hz 3 theem | Raws li koj xav tau |

| 7.Control system

| Hluav taws xob Box | Customized (nto moo hom) |

| Lus | Lus Askiv (Txhawb ntau hom lus) | |

| PLC | Tsis siv neeg ntau lawm ntawm tag nrho lub tshuab. tuaj yeem teeb tsa batch, ntev, kom muaj nuj nqis, thiab lwm yam. | |

| 18.Forming Ceev | 15-20m / min | Qhov ceev yog adjustable raws li tus neeg thov |

MACHINE DETAILS ntawm Zhongke sawv seam yob txoj kev tshuab

COMPANY INTRODUCTION ntawm Zhongke sawv seam yob txoj kev tshuab

Zhongke Roll Forming Factorydriven los ntawm kev tshawb fawb thiab thev naus laus zis tshiab, tsom mus rau cov khoom siv zoo tshaj plaws hauv kev tshawb fawb thiab kev tsim kho thiab tsim khoom. Peb tau cog lus los muab cov kev txawj ntse, ua tau zoo thiab ruaj khov tshuab tsim cov kev daws teeb meem uas ua tau raws li cov kev xav tau sib txawv ntawm kev tsim kho kev lag luam thiab xyuas kom meej tias peb cov khoom muaj zog thiab ruaj khov los pab kev tsim kho kev lag luam.

PACKAGING & LOGISTICS ntawm Zhongke sawv seam yob txoj kev tshuab

PACKAGING & LOGISTICS ntawm Zhongke Ob Txheej Roll Forming Tshuab

FAQ

Q1.Yuav ua li cas thiaj tau txais cov lus hais?

A1) Muab rau kuv qhov loj me thiab tuab, nws tseem ceeb heev.

A2) Yog tias koj muaj kev xav tau rau kev tsim khoom ceev, lub zog, qhov hluav taws xob thiab hom, thov piav qhia ua ntej.

A3) Yog tias koj tsis muaj koj tus kheej daim duab kos, peb tuaj yeem pom zoo qee cov qauv raws li koj tus qauv kev lag luam hauv zos.

Q2. Koj cov nqe lus them nqi thiab lub sijhawm xa khoom yog dab tsi?

A1: 30% raws li qhov tso nyiaj los ntawm T / T ua ntej, 70% raws li qhov nyiaj tshuav ntawm T / T tom qab koj kuaj xyuas lub tshuab zoo thiab ua ntej xa khoom. Tau kawg koj cov nqe lus them nqi xws li L / C tau txais.

Tom qab peb tau txais cov nyiaj them poob qis, peb yuav npaj ntau lawm. Txog 30-45 hnub rau kev xa khoom.

Q3. Koj puas muag cov tshuab txheem xwb?

A3: Tsis yog, feem ntau ntawm peb cov tshuab tau tsim raws li cov neeg siv khoom tshwj xeeb, siv cov khoom lag luam sab saum toj.

Q4. Koj yuav ua li cas yog tias lub tshuab tawg?

A4: Peb muab 24 lub hlis lav dawb thiab kev pabcuam pub dawb rau tag nrho lub neej ntawm txhua lub tshuab.Yog tias cov khoom tawg tsis tuaj yeem kho, peb tuaj yeem xa cov khoom tshiab hloov cov khoom tawg tau dawb, tab sis koj xav tau them tus nqi nthuav qhia los ntawm koj tus kheej. Yog tias nws dhau lub sijhawm lav, peb tuaj yeem sib tham los daws qhov teeb meem, thiab peb muab kev txhawb nqa rau tag nrho lub neej ntawm cov khoom siv.

Q5. Koj puas tuaj yeem lav qhov kev thauj mus los?

A5: Yog, thov qhia kuv qhov chaw nres nkoj lossis chaw nyob. peb muaj kev nplua nuj hauv kev thauj mus los.