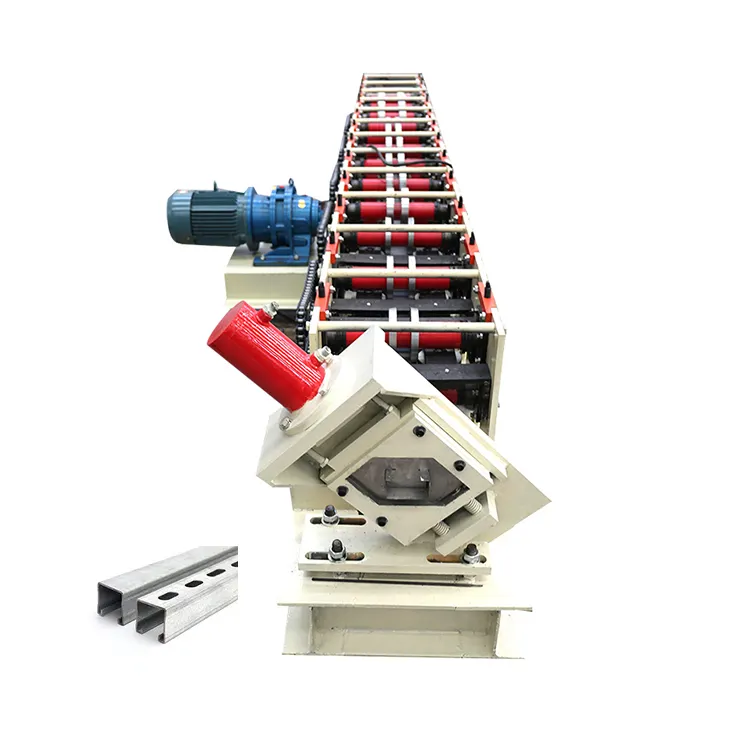

Warehouse Shelving Racking Beam Roll Forming Machine Upright Rack Roll Forming Tshuab

| Tsim cov chaw nres tsheb | Txog 20-22 chaw nres tsheb lossis raws li koj qhov profile kos duab |

| Tshuab qauv | Yeem 1: phab ntsa vaj huam sib luag qauv Yeem 2: cam khwb cia hlau strcture |

| Rollers khoom | GCr15, quenching kev kho mob: HRC58-62; Cr12, SKD11 (yeem) |

| Txoj kev tsav | Chain tsav lossis Gearbox tsav (yeem) |

| Raw khoom thov | Txias dov los yog kub dov steel, galvanized steel, SS316L, Mild Steel |

| Tag nrho cov kab ua haujlwm ceev | 0-25m / min |

| Ntev precision | 6 +-1.0mm |

| Punching system | Hydraulic xuas nrig ntaus lossis xuas nrig ntaus tshuab (xaiv) |

| Txiav qhov system | Tsis nres txiav lossis servo Tracking txiav |

| Inverter | Siemens, Mitsubishi, panasonic (xaiv hom) |

| PLC | Siemens, Mitsubishi, panasonic (xaiv hom) |

| Main Power nrog reducer | 18.5KW WH Suav nto moo |

| Txiav tuav | Servo tom qab txiav |

| Lub cev muaj zog ntawm qhov chaw nres tsheb hydraulic | 5.5 KW TSI |

| Txiav hom | Hydraulic tsav, txiav tom qab tsim |

| Cov khoom ntawm cov hniav txiav | Cr12Mov, txheej txheem quenching |

Khoom kab

Peb cov khoom raug muag rau ntau lub teb chaws thiab cheeb tsam thoob plaws ntiaj teb, thiab peb tau tsim kev sib raug zoo nrog cov neeg siv khoom mus sij hawm ntev!

Ntim & Logistics

FAQ

Q1. Koj puas yog tuam txhab lag luam lossis lub Hoobkas?

A1. Peb yog cov chaw tsim khoom, tsis yog lub tuam txhab lag luam txawv teb chaws xwb. Peb muaj lub Hoobkas.

Q2. Vim li cas koj tus nqi siab dua lwm tus neeg muag khoom '?

A2. Peb cov tshuab siv cov khoom lag luam txawv teb chaws thiab cov khoom lag luam hauv tsev thawj qib nrog kev ua haujlwm zoo, tsim nyog tsim. Tus nqi kuj txawv raws li qhov sib txawv ceev thiab cov qauv.

Q3. Koj cov tshuab puas muaj qhov zoo?

A3. Muaj tseeb tiag. Peb them siab rau qhov zoo. Peb muaj ntau tus neeg siv khoom tsis tu ncua hauv tsev thiab txawv teb chaws. Peb xav tias tsuas yog cov tshuab ua haujlwm siab yuav tau txais kev koom tes ntev nrog cov neeg siv khoom.

Q4. Cov ntaub ntawv dab tsi cov neeg siv khoom xav tau muab yog tias lawv xav tau cov lus hais?

A4. Cov neeg siv khoom yuav tsum muab peb cov duab kos duab nrog cov lus qhia meej, cov khoom siv, cov khoom siv lub thickness thiab xuas nrig ntaus qhov.

Q5. Koj puas tuaj yeem ua customized profile machine?

A5. Yog lawm, peb tuaj yeem tsim cov tshuab raws li cov neeg siv khoom xav tau

Q6. Koj puas muaj kev pab cuam tom qab muag?

A6. Muaj tseeb tiag. Peb yuav muab kev pabcuam dawb tom qab muag ib xyoos. Txawm tias tom qab ib xyoos, peb kuj tuaj yeem pab txhawb koj thaum lub tshuab muaj teeb meem. Peb mam li them tsuas yog thaum qee qhov seem yuav tsum tau hloov.

q7 ua. Peb tuaj yeem ntseeg tau li cas koj tuaj yeem ua lub tshuab?

A7. Ua ntej, peb yuav tsis lees txais qhov kev txiav txim yog tias peb ua tsis tau lub tshuab. Peb yuav plam dua cov neeg siv khoom yog tias peb ua tsis tiav. Qhov thib ob, tag nrho peb cov tshuab yuav tsum tau kuaj xyuas ua ntej xa khoom. Cov neeg siv khoom tuaj yeem npaj lawv cov phooj ywg lossis cov kev pabcuam tshuaj xyuas tuaj rau peb lub Hoobkas los kuaj xyuas lub tshuab.