ZKRFM TR4 Trapezoidal Ib Txheej Yob Txoj Tshuab

Cov lus piav qhia ntawm cov khoom los ntawm tus neeg muag khoom Txheej txheem cej luam

KHOOM ZOO TSHAJ PLAWS NTAWM Zhongke TR4 Ib Txheej Roll Forming Tshuab

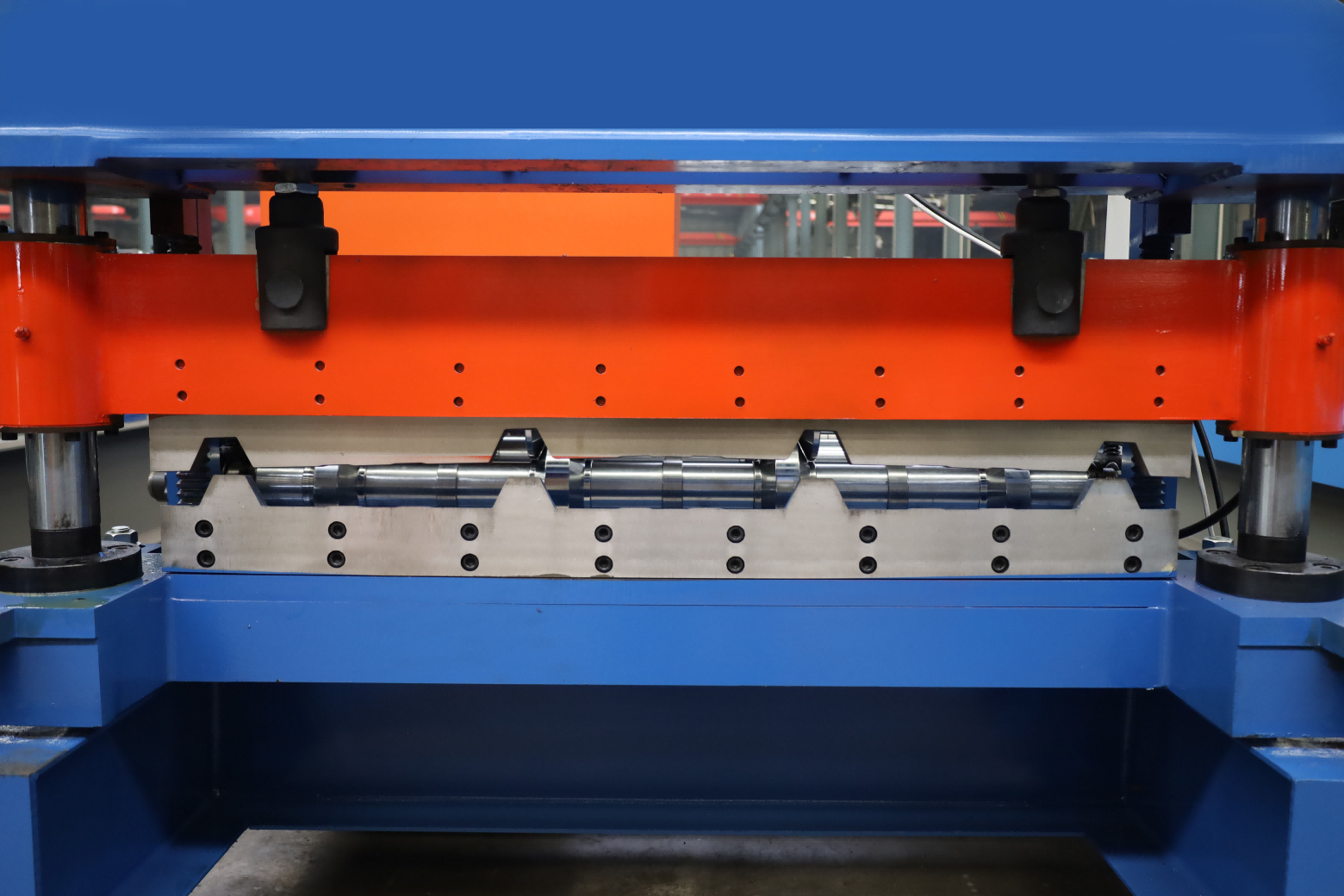

1. Cov hniav tsuas muaj cr12mov, uas yog qhov zoo, muaj zog thiab hnav-resistant.

2. Cov saw hlau thiab nruab nrab phaj yog dav thiab tuab, thiab kev ua haujlwm ntau lawm ruaj khov.

3. Lub log siv sijhawm dhau sijhawm electroplating, thiab txheej txheej nce mus txog +0.05 hli.

4. Tag nrho lub tshuab txais kev txhaj tshuaj blasting tshuab kom tshem tawm xeb, thiab tshuaj tsuag ob sab ntawm primer thiab ob sab ntawm lub topcoat kom ntxiv dag zog rau lub adhesion ntawm lub tshuab rau cov xim, tsis tsuas zoo nkauj nyob rau hauv tsos, tab sis kuj tsis yooj yim rau hnav.

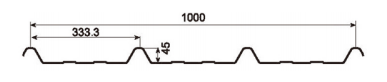

PURLIN SPECIFICATIONS NTAWM Zhongke TR4 Ib txheej yob txoj kev tshuab

MACHINE DETAILS ntawm ZhongkeTR4 Ib Txheej Roll Forming Tshuab

| Coiler Khoom siv: steel ncej thiab nylon ncej Nuclear load 5t, ob dawb | |

Daim Ntawv Qhia Ntaus

| |

| Kev tsim qhov system Kev Hloov Mus Los yog ib qho tseem ceeb ntawm peb lub tshuab yob txoj kev, kom ntseeg tau meej thiab automated positioning ntawm cov ntaub ntawv. Nws txhim khu kev ua tau zoo thiab raug nyob rau hauv cov txheej txheem ntau lawm, ua rau nws muaj txiaj ntsig zoo rau peb cov neeg siv khoom. | |

| Txiav Qhov system 1.Function: txiav txiav yog tswj los ntawm PLC. Lub tshuab tseem ceeb txiav nres thiab txiav yuav tshwm sim. Tom qab lub txiav, lub ntsiab tshuab yuav cia li pib. 2. Fais fab mov: hluav taws xob lub cev muaj zog 3.Frame: coj ncej 4.Stroke hloov: tsis tiv tauj photoelectric hloov 5.Cutting tom qab sib sau: txiav daim ntawv tom qab yob txoj kev kom yuav tsum tau ntev 6.Length ntsuas: tsis siv neeg ntev ntsuas

| |

| Hluav taws xob Tswj Qhov system Tag nrho cov kab yog tswj los ntawm PLC thiab kov npo. Lub PLC system yog nrog high-ceev kev sib txuas lus module, nws yog ib qho yooj yim rau kev ua haujlwm. Cov ntaub ntawv technical thiab system parameter tuaj yeem tsim los ntawm kov npo, thiab nws yog nrog ceeb toom ua haujlwm los tswj kev ua haujlwm ntawm tag nrho kab. 1.Control lub txiav ntev txiav 2. Tsis siv neeg Length ntsuas thiab suav kom muaj nuj nqis (precision 3m +/- 3mm) 3. Voltage: 380V, 3 Phase, 50Hz (Raws li tus neeg yuav khoom thov)

|

COMPANY INTRODUCTION ntawm Zhongke TR4 Ib Txheej Roll Forming Tshuab

Zhongke Roll Forming Factorydriven los ntawm kev tshawb fawb thiab thev naus laus zis tshiab, tsom mus rau cov khoom siv zoo tshaj plaws hauv kev tshawb fawb thiab kev tsim kho thiab tsim khoom. Peb tau cog lus los muab cov kev txawj ntse, ua tau zoo thiab ruaj khov tshuab tsim cov kev daws teeb meem uas ua tau raws li cov kev xav tau sib txawv ntawm kev tsim kho kev lag luam thiab xyuas kom meej tias peb cov khoom muaj zog thiab ruaj khov los pab kev tsim kho kev lag luam vam meej.

Peb cov neeg siv khoom ntawm ru tsev ntawv yob txoj kev tshuab

Peb cov khoom raug muag rau ntau lub teb chaws thiab cheeb tsam thoob plaws ntiaj teb, thiab peb tau tsim kev sib raug zoo nrog cov neeg siv khoom mus sij hawm ntev!

PACKAGING & LOGISTICS ntawm Qhov Rooj Ncej Roll Forming Tshuab

FAQ

Q1.Yuav ua li cas thiaj tau txais cov lus hais?

A1) Muab rau kuv qhov loj me thiab tuab, nws tseem ceeb heev.

A2) Yog tias koj muaj kev xav tau rau kev tsim khoom ceev, lub zog, qhov hluav taws xob thiab hom, thov piav qhia ua ntej.

A3) Yog tias koj tsis muaj koj tus kheej daim duab kos, peb tuaj yeem pom zoo qee cov qauv raws li koj tus qauv kev lag luam hauv zos.

Q2. Koj cov nqe lus them nqi thiab lub sijhawm xa khoom yog dab tsi?

A1: 30% raws li qhov tso nyiaj los ntawm T / T ua ntej, 70% raws li qhov nyiaj tshuav ntawm T / T tom qab koj kuaj xyuas lub tshuab zoo thiab ua ntej xa khoom. Tau kawg koj cov nqe lus them nqi xws li L / C tau txais.

Tom qab peb tau txais cov nyiaj them poob qis, peb yuav npaj ntau lawm. Txog 30-45 hnub rau kev xa khoom.

Q3. Koj puas muag cov tshuab txheem xwb?

A3: Tsis yog, feem ntau ntawm peb cov tshuab tau tsim raws li cov neeg siv khoom tshwj xeeb, siv cov khoom lag luam sab saum toj.

Q4. Koj yuav ua li cas yog tias lub tshuab tawg?

A4: Peb muab 24 lub hlis lav dawb thiab kev pabcuam pub dawb rau tag nrho lub neej ntawm txhua lub tshuab.Yog tias cov khoom tawg tsis tuaj yeem kho, peb tuaj yeem xa cov khoom tshiab hloov cov khoom tawg tau dawb, tab sis koj xav tau them tus nqi nthuav qhia los ntawm koj tus kheej. Yog tias nws dhau lub sijhawm lav, peb tuaj yeem sib tham los daws qhov teeb meem, thiab peb muab kev txhawb nqa rau tag nrho lub neej ntawm cov khoom siv.

Q5. Koj puas tuaj yeem lav qhov kev thauj mus los?

A5: Yog, thov qhia kuv qhov chaw nres nkoj lossis chaw nyob. peb muaj kev nplua nuj hauv kev thauj mus los.